Modular Masonry Retaining Wall Detail

Retaining Walls solve the need for a change in grade.

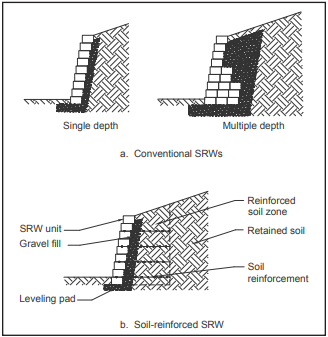

Retaining Walls solve the need for a change in grade where space does not allow the grade to simply be sloped, which is the least expensive way to change elevations of the ground. Traditional cast-in-place concrete retaining walls are giving way to the modular masonry variety for three reasons. Modular masonry is less expensive, more attractive and more flexible - literally and figuratively.

Curving shapes are possible, and the dry-stacked blocks adjust to settlement and relieve water pressure in the retained earth.

Walls over 4' high require geotextile cloth tie-backs into the backfill. The vertical spacing and depth of the tie-back will be specified by the modular masonry manufacturer. A specialty contractor is necessary for good results. The top of the wall requires special attention when a guard rail is incorporated.

Additional design considerations can be found in this PDF from NCMA TEK.

COMMENTS:

This detail is suggested to specify the construction and materials required for minor retaining walls. Wall over eight feet in exposed height should be reviewed by a specialist. The soil reinforcement grid is used for wall four feet or more in height and is the key to the stability of the wall. (Dark horizontal lines in detail)

This detail may eliminate the need for specifications covering these conditions.

This detail is referenced the site plan.

Most codes require a guard rail for changes in grade of more than 24". Consider placing a fence behind the wall or incorporating a guard rail into the top of the wall.

These details should be placed on the Site Plan sheet(s), the A100 or AS100 series of sheets per the National CAD Standards.

Download PDF of detail.

See the Terms of Use for disclaimer.